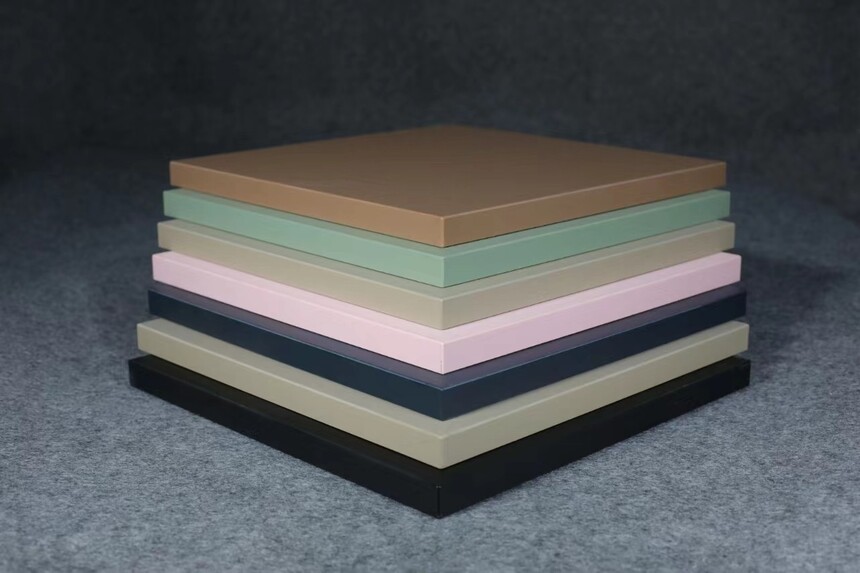

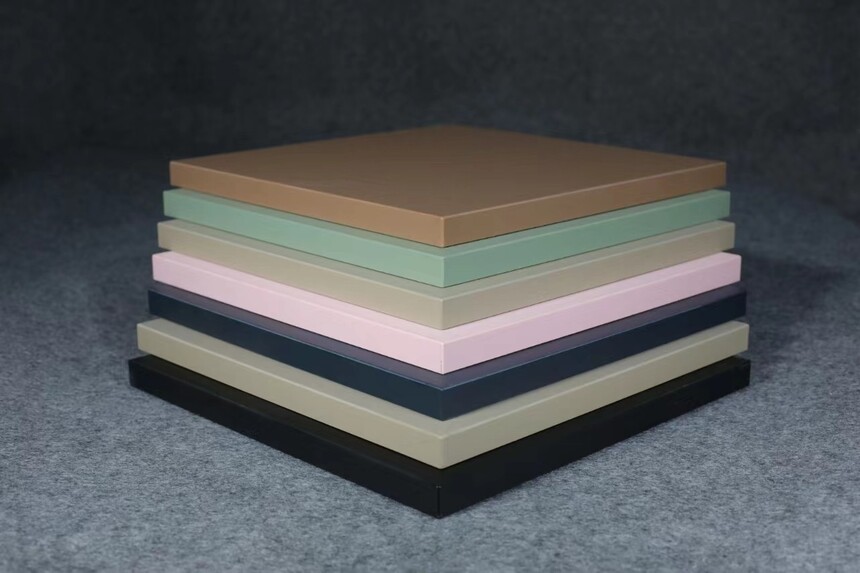

PVC edge banding is relatively lightweight compared to materials such as glass. It is so light because it is an organic compound, which means it is composed of lighter elements such as carbon, hydrogen, oxygen, and nitrogen. Of course, there may also be some problems encountered during the production process. This article will explain the common problems and their causes!

Common problems and solutions in the production process of PVC edge banding strips

1、 Shaved edges turn white

(Only 3:2 formula and 1:1 formula are available)

1) When the carbon powder is heavy, first adjust the background color with titanium dioxide, and then increase the amount of carbon powder.

2) Use high-quality PEWAX to improve surface glossiness.

3) Raise the extrusion temperature or lower the extrusion speed to promote its plasticization. The better the plasticizing effect.

2、 Needles, punctures, blisters

(Mainly caused by improper operation)

Cause analysis:

1) The temperature of PVC mixing is not suitable. For example, the temperature of the 3:2 formula is about 140 ℃, and the temperature of the 2:1 formula is about 135 ℃. Unreasonable stirring temperature can lead to foaming and pinholes.

2) The packaging bag or powdered cylinder head has not been cleaned, and raw powder and impurities have leaked in.

3) The carbon powder is not stirred evenly.

4) The sieve was broken, and large particles of calcium powder were mixed into the ingredients. During the production process, 80-120 mesh sieves are often added to increase pressure and screen out impurities that are too coarse. So the above content is an interpretation of common questions about PVC edge banding, hoping that everyone can use it as an important reference!