|

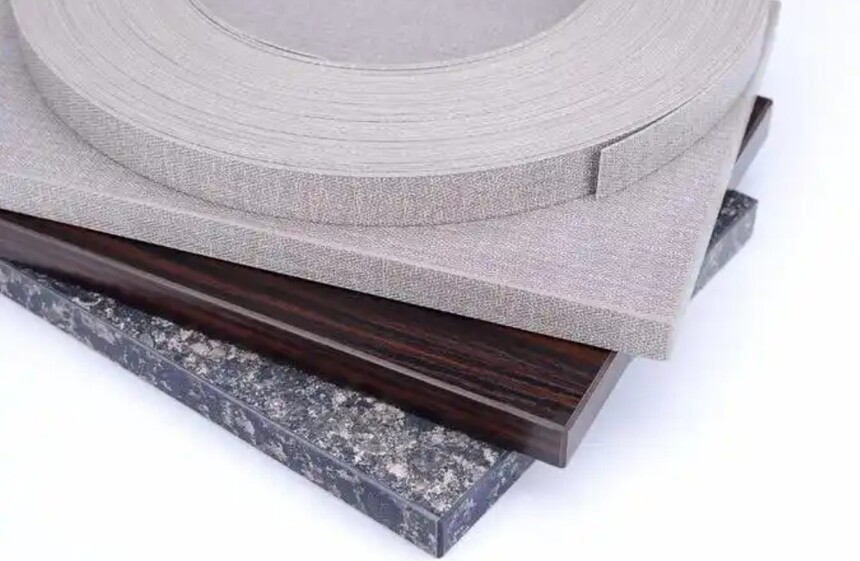

Factors affecting the quality of furniture edge bandingCommon Problems in Furniture Edge Banding and Their Analysis

I. Edge banding tends to fall off during the trimming process 1¡¢The adhesive is applied too thinly; 2¡¢The material is too cold or damp (especially when the adhesive has just been applied); 3¡¢If the glue line is clearly visible and shows the pattern of the glue application roller, it may be that the temperature of the glue application roller is too low; 4¡¢The speed of the conveyor belt is too slow; 5¡¢The ambient temperature or the temperature of the material is too low (working below 15¡ãC); 6¡¢Insufficient pressure.

II. The initial position of the edge banding is unstable and unsatisfactory 1¡¢The roller pressure wheel needs to be adjusted with skill, and the extension position should be adjusted to increase the roller pressure. 2¡¢The effect of the 5cm position at the beginning or end where the rubber surface of the rubber roller adheres to the panel is often unsatisfactory. This is because the rubber roller is prone to insufficient pressure at the head and tail positions, and when in a high-speed production state, the rubber roller is prone to jumping when in contact with the panel.

III. The bonding effect on one side is good while the other is poor 1¡¢Poor contact between the panel (substrate) and the pressure wheel; 2¡¢Uneven glue application leads to glue seepage, which hinders the edge banding process.

IV. Intermittent poor adhesion 1¡¢The temperature of the hot-melt adhesive in its liquid state is too low; 2¡¢When the edge banding machine is adjusted to run too fast with an excessive amount of glue applied, the hot-melt cylinder fails to melt the hot-melt adhesive in time, resulting in uneven glue application; 3¡¢Unstable temperature of the hot-melt device.

V. The edge banding tends to detach shortly after bonding 1¡¢Excessively high temperature of the hot-melt adhesive, edge banding, substrate, goods, or pressure roller; 2¡¢Too high ambient temperature (room temperature) during construction; 3¡¢Excessive amount of glue applied; 4¡¢Too high humidity of the edge banding or substrate; 5¡¢The substrate and edge banding themselves contain resin (oil) components, which reduces the adhesion. This often occurs in the process of using veneer/solid wood edge banding.

VI. Scratches on the surface of the edge banding 1¡¢The edge banding material is too thin and has weak surface abrasion resistance; 2¡¢Rough edges of the panel; 3¡¢Lack of elasticity in the adhesive film.

VII. Pen-point shaped marks or bulges on the surface of the edge banding

This is because the hot-melt adhesive has been contaminated by dust particles, wood chips, or other impurities, resulting in unevenness after pressure is applied. Therefore, it is necessary to ensure the cleanliness of the hot-melt device.

Yida Decoration Materials Co., Ltd. is a professional enterprise specializing in the production of decorative edge banding. Its products mainly include PVC edge banding, ABS edge banding and laser edge banding. The products are not only best-selling in the domestic market, but also exported to overseas customers in Russia, Portugal, Egypt, Saudi Arabia and other countries. Our company has a complete range of products, rich colors and various styles, and the existing products are sold far to international markets such as the Middle East, Russia and Southeast Asia. We can carry out design and production according to the different needs of customers. The products have the advantages of wear resistance, light resistance, clear texture, lifelike image and consistent trimming, which achieve good sensory effects and enhance the competitiveness of products in the market. Our company will continue to forge ahead, strive to provide better services for the majority of users who have grown with our company, and is willing to cooperate with new and old customers with excellent quality, thoughtful service and outstanding products to create a better tomorrow together.

|